Fluid Power Machine Safety Standards

Standards provide recommended processes, procedures, and information on the legal requirements found in the Machinery Directive, and OSHA Standards are created by companies and organisations that have a vested interest in those standards and typically include end users, OEMs, and component suppliers.

- ISO (International Standards Organisation)

- IEC (International Electrical Commission)

- ANSI (American National Standards Organisation)

- NFPA (National Fire Protection Association)

- NFPA (National Fluid Power Association)

- CSA (Canadian Standards Association)

- UL (Underwriters Laboratories)

- EN for Europe

- DIN for Germany

- JIS for Japan

- NR for Brazil

- AS for Australia

- GB for China

- and many others for other countries

Standard Types

Standards are created to address a specific part of a safety system or a specific type of machine, allowing them to provide much more detailed requirements and recommendations.

Standards are grouped into three types: A, B, and C standards.

Type-A standards (basis standards) like ISO 12100 and ANSI B11.0 give basic concepts, principles for design, and general aspects that can be applied to all machinery.

- Type-B1 standards for particular safety aspects (e.g., safety distances, surface temperature, noise).

- Type-B2 standards for safeguards (e.g., two-hands controls, interlocking devices, pressure sensitive devices, guards).

Type-C standards (machinery safety standards) deal with detailed safety requirements for a particular machine or group of machines like ISO 16092-4 for pneumatic presses.

International Safety Standards Levels

Basic Standards

- Basic concepts

- Principles for design

- General aspects

Application Standards

- Safety distances

- Surface temperature

- Noise

- Two-handed controls

- Interlocking devices

- Pressure sensitive devices

- Guards

Specific Machine Standards

- Vertical standards covering a single type of machine or group of machines

- Use A and B standards to create C standards

Type C standards shall be used for specific machine types. Type A & B standards may also be used to help implement some of the requirements of a type C standard. For instance, a safety interlock may be referenced to be used on a plastic blow moulding machine which has a type C standard but uses the specifics of a type B standard that show how to implement the safety interlock. Type A & B standards would also be used for any machine where no type C standard exists.

A and B-type standards outline the safety development process and are frequently referenced by many other global standards. These standards are often used with other standards listed below to implement complete machinery safety solutions.

- 29CFR 1910.212 General Requirements for All Machines

- 29CFR 1910.147 Control of Hazardous Energy

- 29CFR 1910.213-218 Machine Specific Standards (Type-C Standards)

- 29CFR 1910.219 Mechanical Power-Transmission Apparatus

- 29CFR 1910.303-308 Electrical Safety

- 29CFR 1910.333 Electrical Safe Work Practises

- 29CFR 1910.95 Occupational Noise Exposure

- ANSI/NFPA 70: National Electrical Code – 2020

- ANSI/NFPA 70E: Standard for Electrical Safety in the Workplace – 2021

- ANSI/NFPA 79: Electrical Standard for Industrial Machinery – 2021

- ANSI Z535.1 – 2023: Safety Colours

- ANSI Z535.2 – 2023: Safety Signs

- ANSI Z535.4 – 2023: Product Safety Signs & Labels

- ANSI B11.0 – 2023: Safety of Machinery

- ANSI B11.19 – 2019: Performance Requirements for Risk Reduction Measures: Safeguarding and Other Means of Reducing Risk

- ANSI B11.20 – 2017: Safety Requirements for Integrated Manufacturing Systems

- ANSI B11.26 – 2024: Functional Safety: General Principles for Designing Safety-Related Parts of Control Systems

- ANSI/ASME B20.1 – 2018: Safety Standard for Conveyors and Related Equipment

- ANSI/PMMI B155.1 – 2023: Safety Requirements of Packaging Machinery

- ANSI/RIA 15.06 – 2012: Industrial Robots and Robot Systems – Safety Requirements

- ANSI Z244.1 – 2024: The Control of Hazardous Energy - Lockout, Tagout, and Alternative Methods

- CSA Z142:2010 – Code for Power Press Operation: Health, Safety, and Safeguarding Requirements

- CSA Z432:2016 – Safeguarding of Machinery

- CSA Z434:2014 – Industrial Robots and Robot Systems

- CSA Z460:2020 – Control of Hazardous Energy – Lockout and Other Methods

- ISO 12100:2010: Safety of Machinery; General Principles for Design, Risk Assessment and Risk Reduction

- ISO 13850:2015 Safety of Machinery; Emergency Stop Equipment – Functional Aspects & Principles for Design

- ISO 13851:2019 Safety of Machinery; Two Hand Control Devices – Functional Aspects & Principles of Design

- ISO 13854:2017 Minimum Gaps to Avoid Crushing of Parts of the Human Body

- ISO 13857:2019 Safety of Machinery; Safe Distances to Prevent Hazardous Zones Being Reached by Upper and Lower Limbs

- ISO 13849-1:2023 Safety Related Parts of Control Systems Part 1: General Principles for Design

- ISO 13849-2:2025 Safety Related Parts of Control Systems Part 2: Validation

- ISO 13855:2010 Safety of Machinery – The Positioning of Protective Equipment in Respect of Approach Speeds of the Human Body

- ISO 13856:2013 Safety of Machinery – Pressure Sensitive Protective Devices

- Part 1: Mats and Floors

- Part 2: Edges and Bars

- Part 3: Bumpers

- Part 4: Pressure Sensitive Barriers

- ISO 14118:2017 Safety of Machinery – Prevention of Unexpected Start-Up

- ISO 14119:2013 Safety of Machinery – Interlocking Devices Associated with Guards – Principles for Design and Selection

- ISO 14120:2015 Design and Construction of Fixed and Movable Guards

- EN 61496:2020 Safety of Machinery – Electro-Sensitive Protective Equipment (Parts 1, 2, 3, 7)

- IEC 60204-1:2016 Safety of Machinery – Electrical Equipment of Machines

- IEC 60529:2020/AMD2:2013/COR1:2019 Degrees of Protection Provided by Enclosures

- IEC 61508:2010 Functional Safety Electrical, Electronic and Programmable Electronic Safety Related Systems

- IEC 62061:2021 Safety of Machinery: Functional Safety of Safety Related Electrical, Electronic and Programmable Electronic Control Systems

OSHA/NFPA/NEMA Standards (If the plant/facility is in the United States)

ANSI Standards (If the plant/facility is in the United States)

CSA Standards (If the plant/facility is located in Canada)

International Standards

International Electro-Technical Commission Standards (IEC)

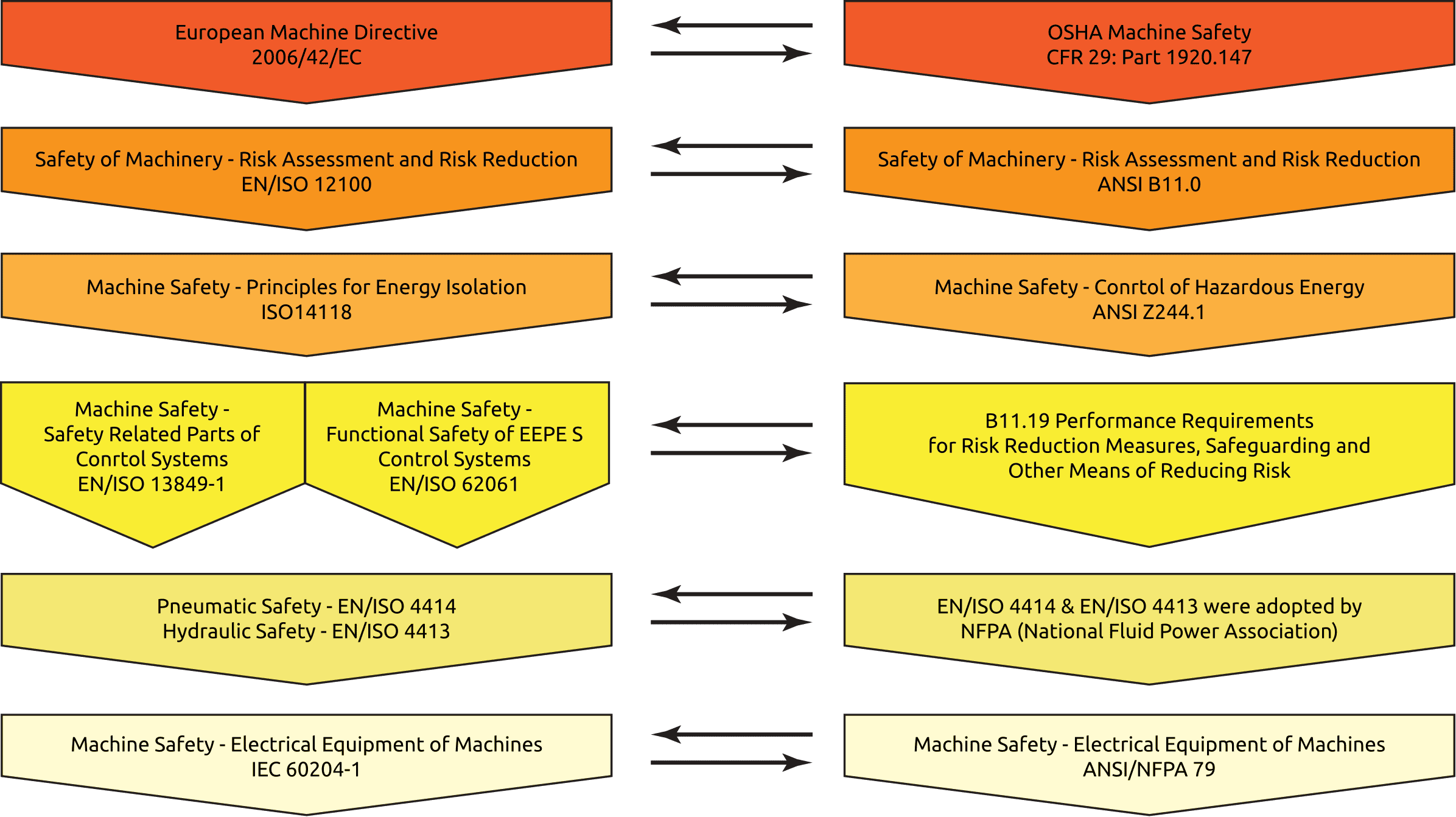

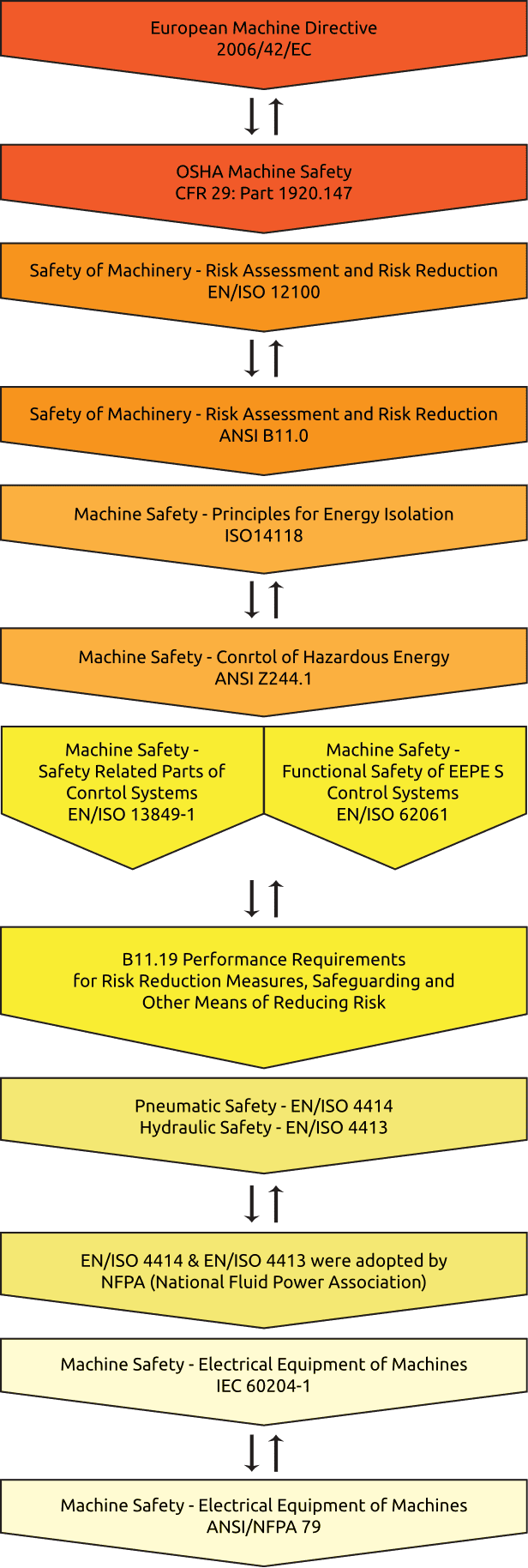

Harmonisation and Differences of Standards

While the list of standards can seem confusing, it is important to understand that following a standard means following a process that guides you through the process of achieving acceptable risk within a machine that will meet the local regulations. The Machinery Directive and OSHA require a risk assessment but do not mention how to do it. Using standards that are harmonised under the Machinery Directive provides for the presumption of conformity. However, you could choose ISO 12100 or ANSI B11.0 to meet either regulation’s requirement. The Machinery Directive does not require you to use ISO, nor does OSHA require you to follow ANSI.

Safety Standards are following a similar flow and have similar content around the globe

Fluid Power Specific Standards

- ISO 4413 Hydraulic Fluid Power – general rules and safety requirements for systems and their components.

- ISO 4414 Pneumatic Fluid Power – general rules and safety requirements for systems and their components.

The standards above have been adopted by the NFPA (National Fluid Power Association). Following these standards helps users meet the requirements of EU, U.S., and some other countries’ regulations. However, these are basic standards that define well-tried practises. These standards do not specify anything regarding the design of a fluid power safety component or system. However, they do provide a normative reference to ISO 12100 for risk assessment and risk reduction and ISO 13849-1 for design and implementation.

ISO 4414:2010 and ISO 4413:2010 have the same general rules and safety requirements, while ISO 13849-1 has two specific statements about Fluid Power Safety. In addition, ANSI B11.0 addresses control systems that perform a safety function along with pneumatic or hydraulic elements used to perform a stop function.

Fluid power output devices are part of the safety-related parts of the control system and must meet the risk reduction level required by the hazard that the safety function is addressing. ISO 12100, ANSI B11.0, ISO 13849-1, ANSI B11.19, and ANSI Z244 is used in the Safety Development Process page to introduce the process of designing a safety system.